Our experience to support and develop your cheese wrapping methods.

At SEREM-SOCOREM, we put our expertise at the service of the cheese industry through a complete range of services designed to meet all your needs.

We offer you a range of comprehensive and personalized services, designed to optimize each stage of your production.

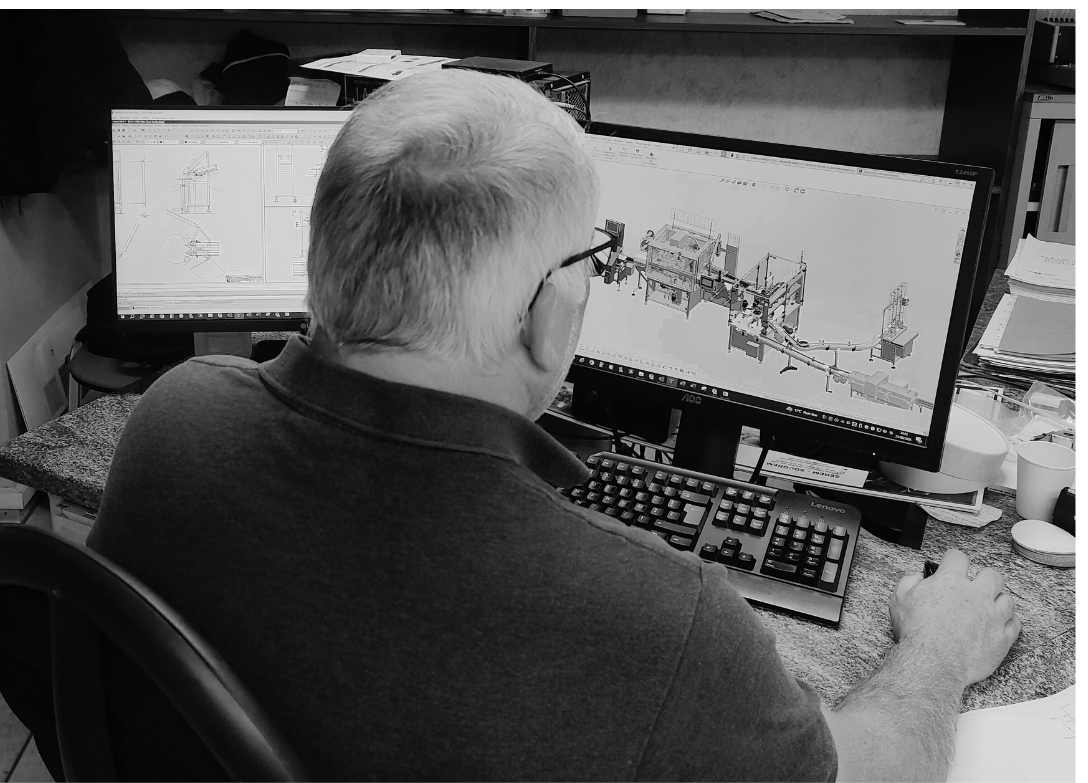

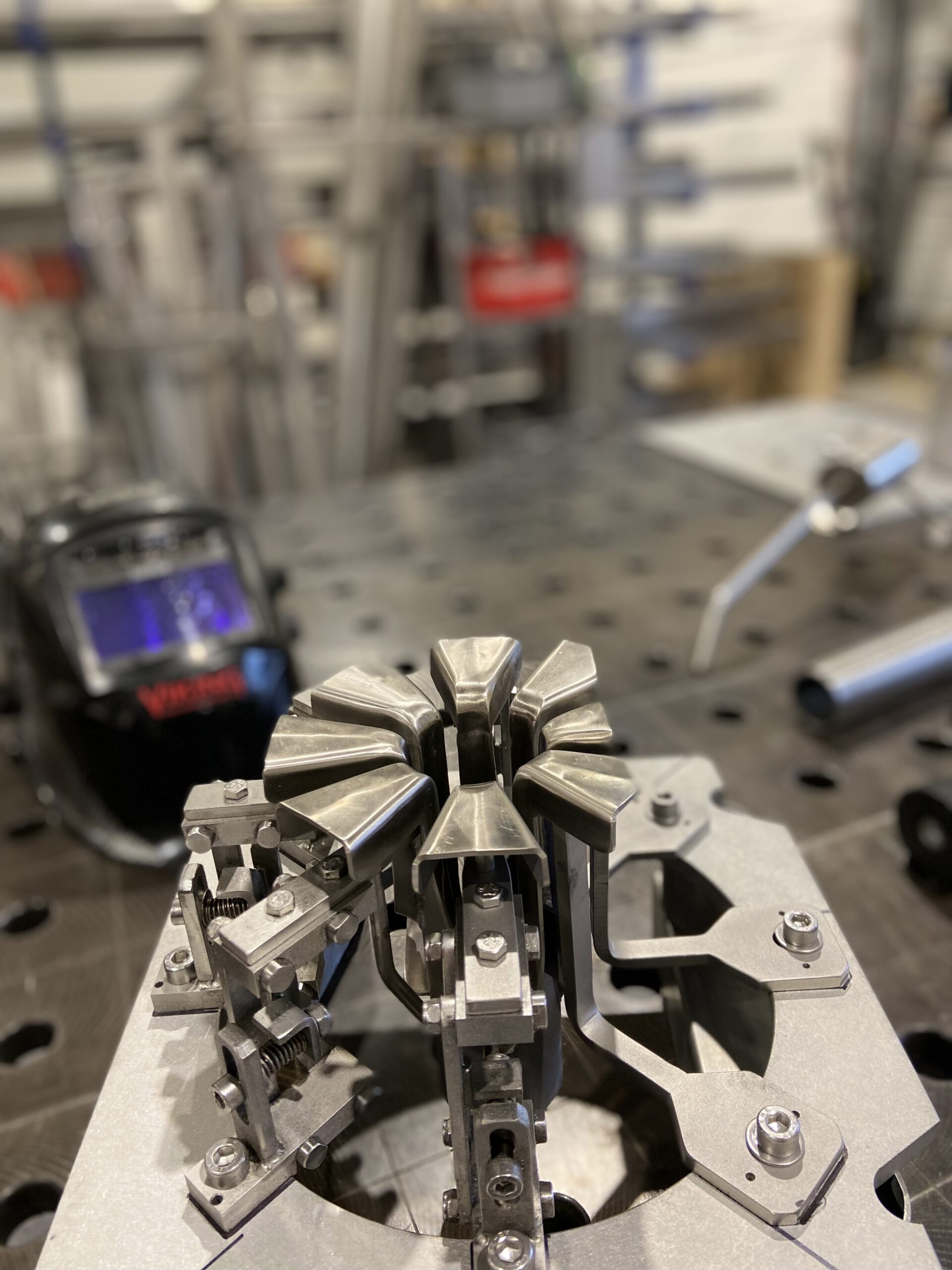

Machines design

We design and manufacture high-precision cheese wrapping machines tailored to the specific requirements of your production.

Each machine is the result of close collaboration with our customers

ensuring a solution perfectly aligned with your requirements.

Supply of spare parts

Because every detail counts, we offer a wide selection of spare parts for your wrapping machines. Whether it’s specific components or standard parts, we provide everything you need to keep your machines in perfect working order.

Reconditioning & improvements

Breathe new life into your old machinery with our retrofit service. We modernize your equipment by integrating the latest technologies, improving its efficiency, safety, and lifespan.

Training

We provide our clients with comprehensive machine training. This training includes the optimal use of their new equipment as well as preventive maintenance procedures, allowing them to maximize the performance and lifespan of their machines. In addition, we provide specific training on spare parts replacement, so they can respond quickly and efficiently when needed. By providing them with these skills, we ensure their autonomy in managing their equipment and minimize downtime due to breakdowns or unplanned maintenance.

Do you have a project ?

Our experience and skills are at your disposal.

Our machines are designed by five integrated design offices:

- Automation

- Electrical Engineering

- Mechanical Engineering

- Robotics

- Vision